rajivcompetentservices@gmail.com View Mobile Number

- Send SMS Send Email

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader |

| Texture | Hard |

| Usage | Industrial Use |

| Packaging Type | Plastic Box |

| Click to view more | |

Product Details

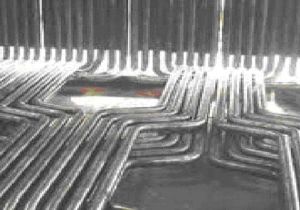

ZQTB is a newly developed high temperature, erosion / corrosion resistant ceramic refractory coating compound. It can withstand high temperatures and also control erosion / corrosion of refractory linings, monolithic, ceramic fibre boards, modules and steel shells. ZQTB is to protect refractory from heat or chemical reactions and to increase the life span of ladles in iron rolling mills or metal processing units.

Main Characteristics & Advantages:

- Easy to apply by toweling, brushing or spraying

- Good adhesion to metals, refractory bricks, monolithic, cast-able and ceramic fibre modules etc.

- Excellent dry strength, Excellent resistance to powdering

- Good adhesion, Chemical resistance, Easy to mix, Gas-tight surface without spalling or cracking at 1800oC, Reduction in slag adhesion

- Considerable increase in service life of refractory linings and heating systems

- Resistant to the influence of steam, acids, alkalis, fumes of sulphur and Vanadium compounds and molten metal, Odourless and non-hazardous

- Porosity approximately 22% at service temperature 1350oC

- Resistant to severe attack and sand blasting effect of burning fuel oil

- Considerable increase in service life of refractory linings and heating systems

ZQTB Compound – The Versatile Refractory Coat

- ZQTB Compound resists harsh chemical attacks at high and low temperatures. Around 3mm thick

- ZQTB Compound coating can work wonders at ambient to 1800° C temperature. 5mm thick ZQTB

- Compound coating offers as good a protection and insulation as a 130mm thick fire brick.

- ZQTB Compound prevents leakage of hot gases from heating chambers, thus maximum heat

- energy is preserved, wear and tear on the ZQTB Compounded surface is minimized and coating lasts longer.

- ZQTB Compound has unlimited applications and is used in the following areas where continuous and high temperature heating is found hazardous, especially in the heating chambers constructed with conventional materials.

- Ceramics / Glass Aluminium, brass and other nonferrous metals

- Chemicals and fertilizers, Pulp and paper, Iron and steel, Marine and shipping, Cement, Sugar, natural and other gases, Petroleum and hydrocarbon

- Coating of kiln furniture, graphite and carbon crucibles.

ZQTB Compound coating will be of great benefit to use in the above areas as well as in domestic boilers, induction furnaces, rotary kilns, chimneys, ducts, etc., where fuel oil, gas or electricity are used for heating purpose.

Looking for "ZQTB Protective Coating Compound" ?

Explore More Products